Don’t hesitate to contact us if you need any assistance or have any questions. We’re here to help!

When we talk about wafer sizes we are referring to the diameter of wafers. The thickness of the wafer is also important but we will ignore that for now. We must first define the components of the wafer dicing process before we can understand the 300mm issue. Once that is done I will show that size does matter in the semiconductor world.

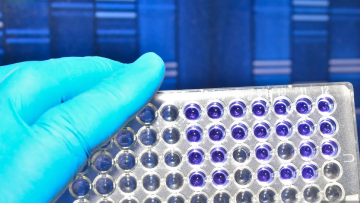

Wafers are thin slices of semiconductor material used to build integrated circuits (IC). The process of cutting out individual dies from a large sheet of silicon wafer is called “dicing”. Wafers can also be made of many different types of materials. Wafers are typically made from silicon but they can also be made of other materials like silicon carbide (SiC), glass, sapphire, Quartz, etc. Silicon carbide has better heat dissipation properties than silicon, so it is used for high power applications. Sapphire is more transparent, which makes it useful for optical devices.

These terms are sometimes used interchangeably but they are not the same process.

The wafer slicing process is one of the first steps in the manufacturing of semiconductor devices. It involves slicing an ingot of silicon into thin slices called wafers. This is usually performed using diamond studded wires or large inside diameter blades. The wafers then go through a mind boggling series of steps to transform its surface into multiple copies of the “finished” semiconductor device. This can be hundreds or thousands of devices often referred to as chips.

The process of separating the individual devices from one another is called wafer dicing, and it is the final step in the long process of making chips. Dicing is the process of cutting silicon wafers into smaller rectangular pieces called dies. Commonly, this is done using a mechanical sawing process using a diamond blade; however, many other methods have been developed to achieve similar results.

The main reason for choosing 300mm wafers instead of 200mm wafers is economical. The yield per wafer is significantly higher than the smaller wafer. To illustrate: Suppose the size of the die piece was 1 cm square. On a 200 mm wafer we get about 240 complete pieces after dicing. However, on a 300mm wafer we get more than 570 complete pieces. That would provide more than twice the improvement in yield with only half the increase in wafer diameter (50%).

Our services are mounting, dicing, inspection, sorting, picking and placing your known good die pieces into various types of bare die chip trays. The trays could be waffle packs, gel packs, etc. A waffle pack is a chip tray that has pockets that match the size of the die pieces. We can also ship the cut wafers on tape and grip rings. We also provide managed outside services such as backgrinding, photoresist, etc. We can process many types of materials. Silicon is the most common material we handle but we also can process most hard brittle materials. Form factor is also important. It can be up to 300mm round or square and less than 10mm in thickness.

We offer the best price/quality ratio. We use state-of-the-art equipment that allows us to perform all of these processes with very short turnaround times. Our customers keep coming back because our quick turn times and exceptional value proposition supports their tight budgets and aggressive deadlines.

If you have a 300mm wafer that requires dicing we would love to cut it on our state of the art machines.

Simply click on the “Request a Quote” button above and fill out the simple form. In the comments section tell us what the final part looks like and then let us know how many you need. A drawing would be great but is not required.

Please take a moment to fill out the form below to receive a personalized quote tailored to your specific needs and requirements.